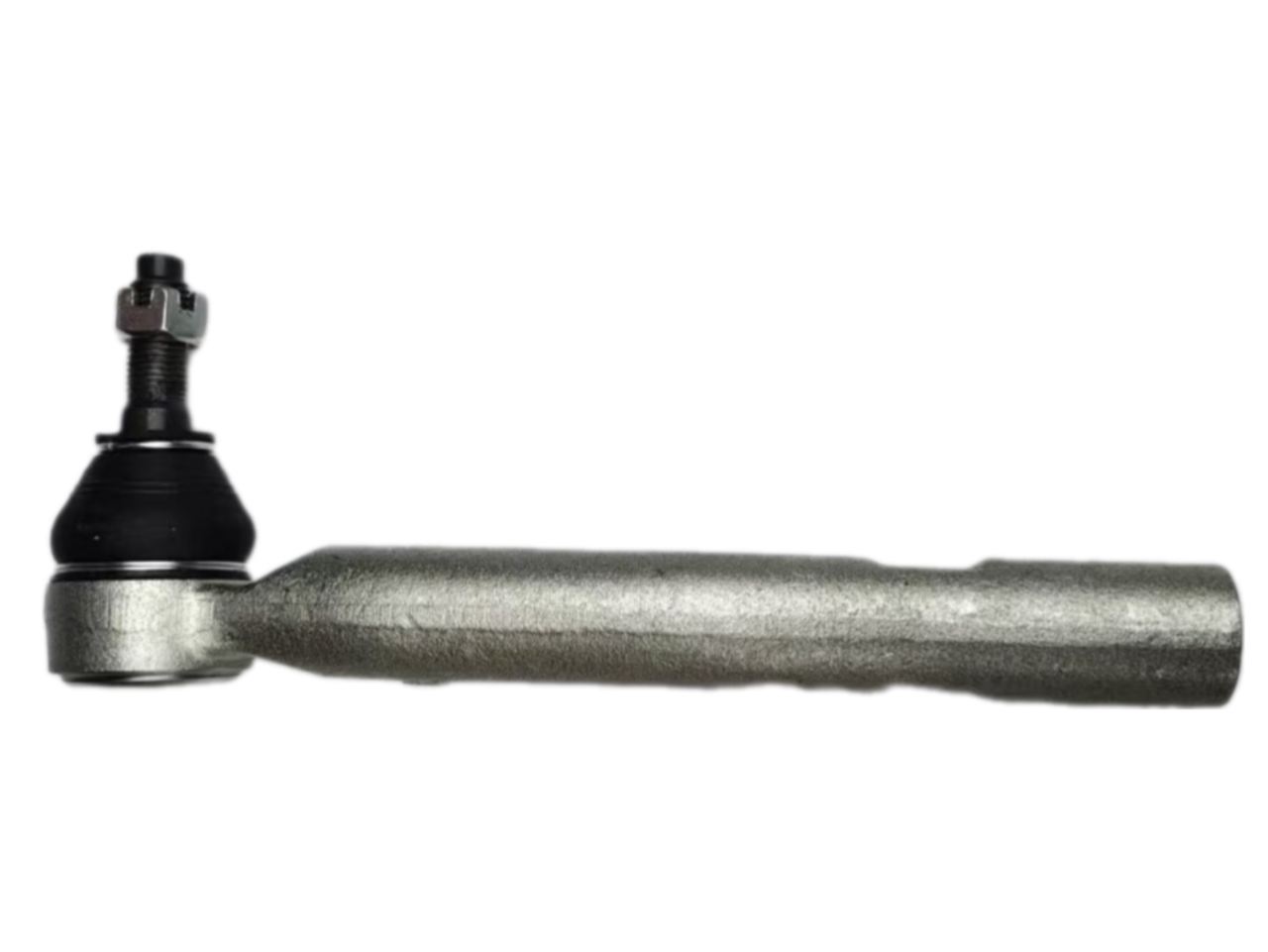

Superior Durability and Strength

Front inner tie rods are engineered with exceptional durability as a primary focus, utilizing high-grade steel and advanced metallurgical processes. The manufacturing process includes precision heat treatment that enhances material strength while maintaining flexibility to absorb road shocks. The threaded sections undergo specialized hardening processes to resist wear and maintain secure connections throughout the component's service life. Advanced coating technologies provide multiple layers of protection against corrosion, particularly important in regions with harsh weather conditions or where road salt is commonly used. The ball joint assemblies incorporate hardened steel races and premium-grade bearings that significantly reduce friction and wear. This robust construction ensures reliable performance under various stress conditions, from everyday commuting to more demanding driving scenarios.