Superior Geometric Design

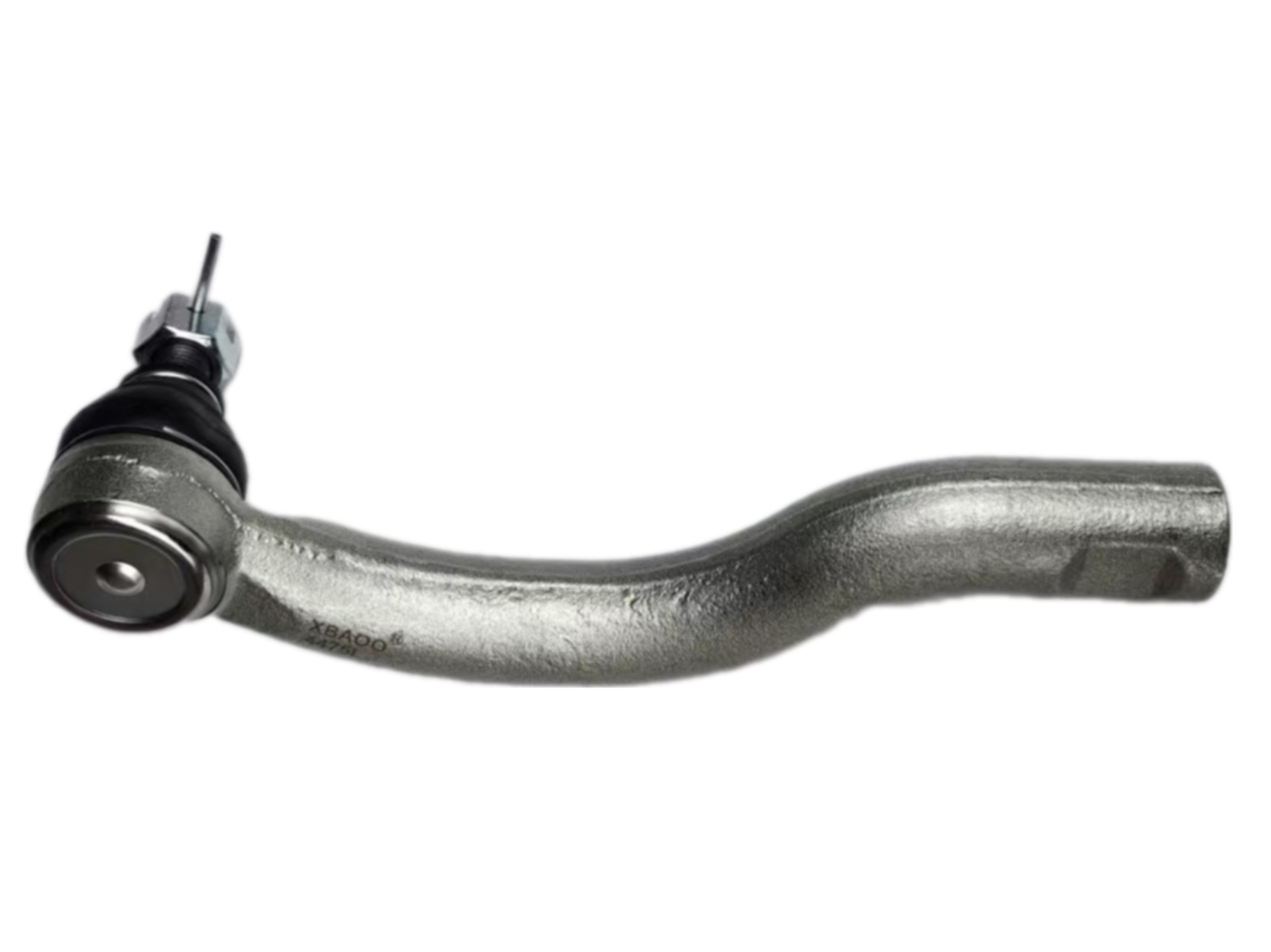

The bent inner tie rod's distinctive geometric design represents a breakthrough in steering system engineering. The carefully calculated bend angle is crucial for maintaining optimal steering geometry while providing necessary clearance for surrounding components. This design enables the suspension to move through its full range of motion without binding or interference, ensuring smooth and consistent steering operation. The precise engineering of the bend angle contributes to proper wheel alignment and toe settings, which are essential for vehicle stability and handling. The geometry also allows for improved load distribution across the component, enhancing durability and reducing stress concentrations that could lead to premature failure. This sophisticated design approach results in better overall steering feel and more precise control, particularly during challenging maneuvers.